The 10-Second Trick For Premier Aluminum Llc

Table of ContentsGetting The Premier Aluminum Llc To WorkThe Facts About Premier Aluminum Llc RevealedThe Greatest Guide To Premier Aluminum LlcThe Definitive Guide for Premier Aluminum LlcUnknown Facts About Premier Aluminum Llc

When picking a light weight aluminum shop for your production needs, it's important to examine numerous aspects. Among the most critical facets to think about is the experience and skills of the foundry. Picking a foundry who has the appropriate understanding of the light weight aluminum casting procedure, and the profile to reveal for it, helps to have a successful end result for your job.Having the experience and market knowledge to craft your spreadings for optimal manufacturing and high quality outcomes will simplify the task. Making aluminum spreading calls for a complex collection of procedures to attain the best results. When choosing a new light weight aluminum factory to partner with, guarantee they have considerable industry experience and are knowledgeable regarding all aspects of the light weight aluminum casting process: layout, manufacturing, product evaluation, and product screening.

The factory needs to also have a tried and tested track document of delivering exceptional products that meet or exceed client expectations. Quality assurance should likewise be at the top of your list when choosing an aluminum shop. By dealing with a qualified shop that follows the criteria for high quality control, you can shield the stability of your item and guarantee it meets your requirements.

All About Premier Aluminum Llc

This certain process can be automated and repeated. Numerous components that really complicated shapes can be manufactured utilizing this process. Big quantities of components can be created in simply a short period of time. Before you start searching for a dependable aluminum pass away wheel, there are some important things that you need to do.

You have to ask yourself what sort of light weight aluminum pass away castings you need. After identifying what you call for, you have to state the specifications of the aluminum die castings you need. Figure out the weight, density, dimension, and various other specs of the aluminum die-cast you require. It would certainly likewise be better if you can attract and reveal all the measurements of the light weight aluminum die-cast.

Do you recognize exactly how much cash you have to invest in the products? In order to do this, the best thing to do is to determine the number of aluminum diecasts you require. After having this info, you can start researching light weight aluminum die-casting makers. You can do this by simply keying the key phrase" Aluminum pass away casting manufacturers" on the Google online search engine.

Some of the inquiries you require to ask yourself are whether they have experienced and well-trained drivers, for how long their organization has been in procedure, or if they have some success. You can commonly get the answers to these concerns from the supplier's website. You can look into other websites or outside resources to verify if the info supplied on the maker's website is authentic.

Little Known Questions About Premier Aluminum Llc.

Another thing you need to take into consideration is the producer's ability to produce aluminum die-casting products. In other words, the quantity of items the maker can create at a given time. Some of the critical concerns you require to ask yourself are whether the producer can create a greater quantity or can the supplier meet your needs.

(https://www.giantbomb.com/profile/premieraluminum/)Suppose your firm calls for 10,000 pieces of particular equipment parts from the producer within one month? You purchased this quantity; however, the maker can just produce 5000 pieces of these device components within one month (Foundries in Wisconsin). Therefore, you won't be able to obtain the quantity that you buy in a timely manner

Premier Aluminum Llc for Beginners

Thus, it is vital that you must make inquiries if the maker is carrying out an in-house tooling process. Furthermore, you have to ask the supplier just how much the cost of internal tooling is. The in-house tooling process, which permits you to develop unique designs and shapes can be an additional price.

This facet straight associates with the producer's production capability. You need to search for a maker that can ensure quicker distribution of products. This should be done in such a method that top notch criteria are preserved. This can ensure that you can obtain your items in a timely manner, and check these guys out you can stay clear of missing those valuable company opportunities.

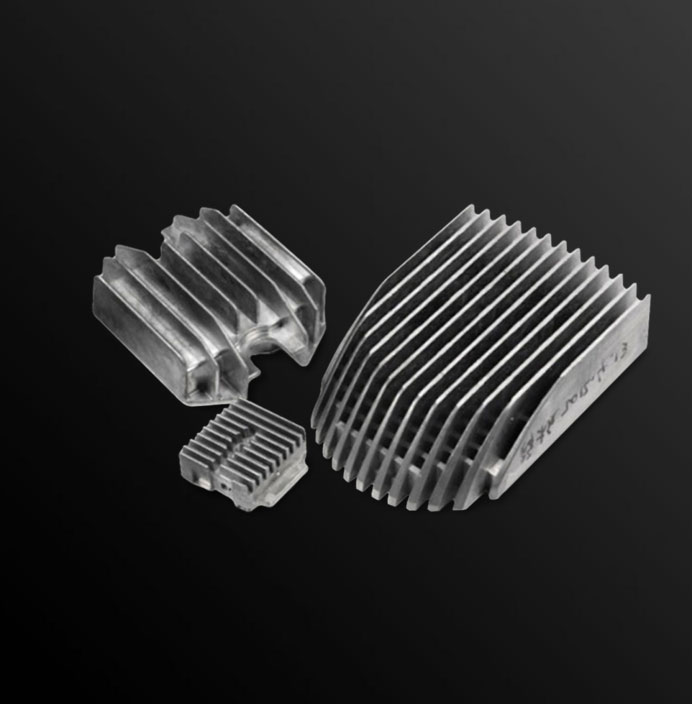

This suggests that there are several options that you can select from. Today, consumer demands continue changing. It seems that consumers are looking for an exceptional mix of high quality, cost-effectiveness, and sturdiness. That is why it is significantly recommended that you should select a maker that can create different kinds of aluminum die-cast products.

Premier Aluminum Llc Fundamentals Explained

Frequently, these light weight aluminum die-casting products will require some decors, machining, or ending up touches. Having this in mind, you need to search for a producer that can carry out a variety of second ending up jobs once die casting is done. Some instances of completing procedures consist of Chromating, CNC Machining, Sandblasting, Powder covering, Anodized, E-coating, Damp painting, Plating, and much more.

Die spreading is one of the most economical, accurate, and protean manufacturing procedures in the world moment. The process includes suitable molten essence, under stress, into an applicable die (planet), and formerly strengthened it can be ejected and ended up (if necessary) in a selection of means.